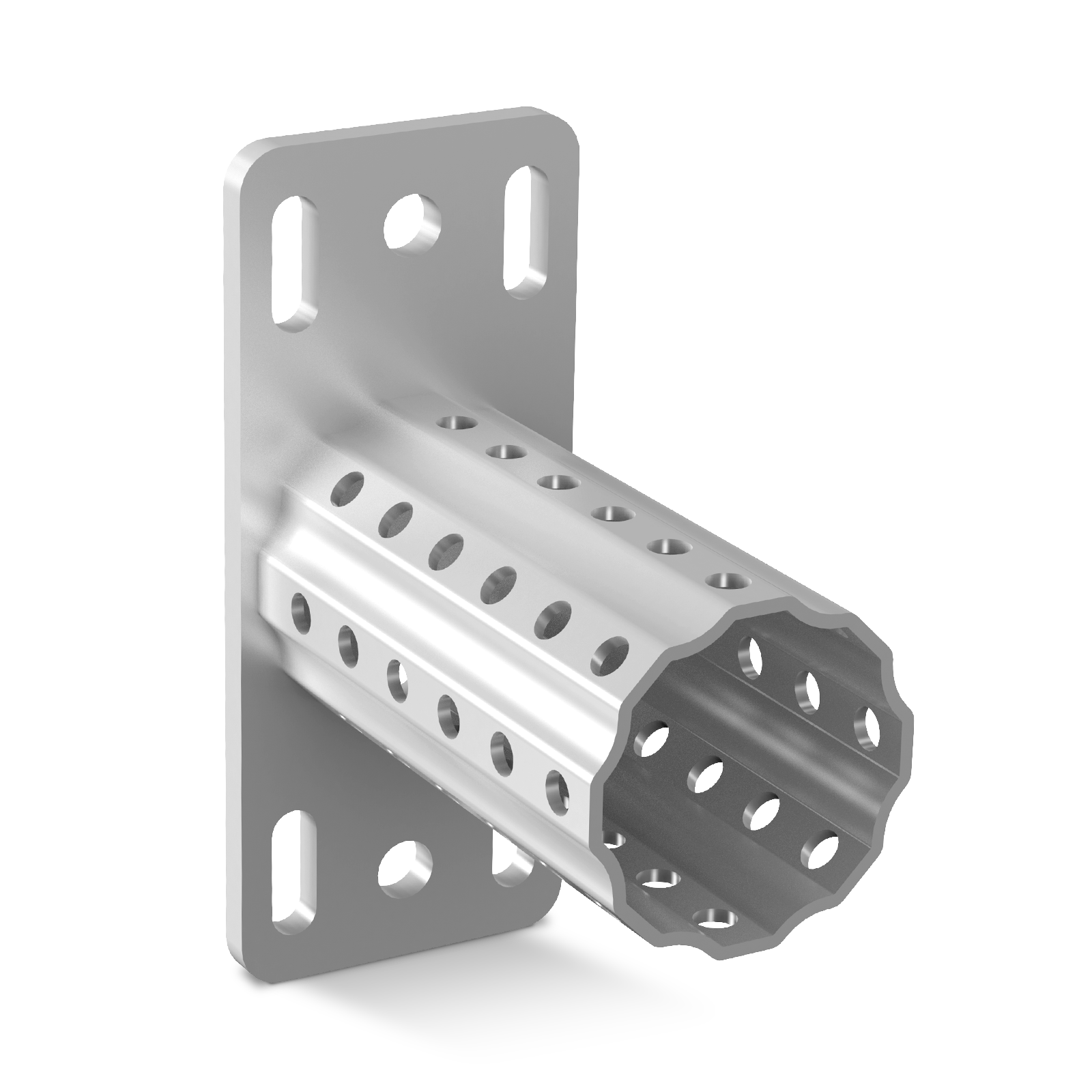

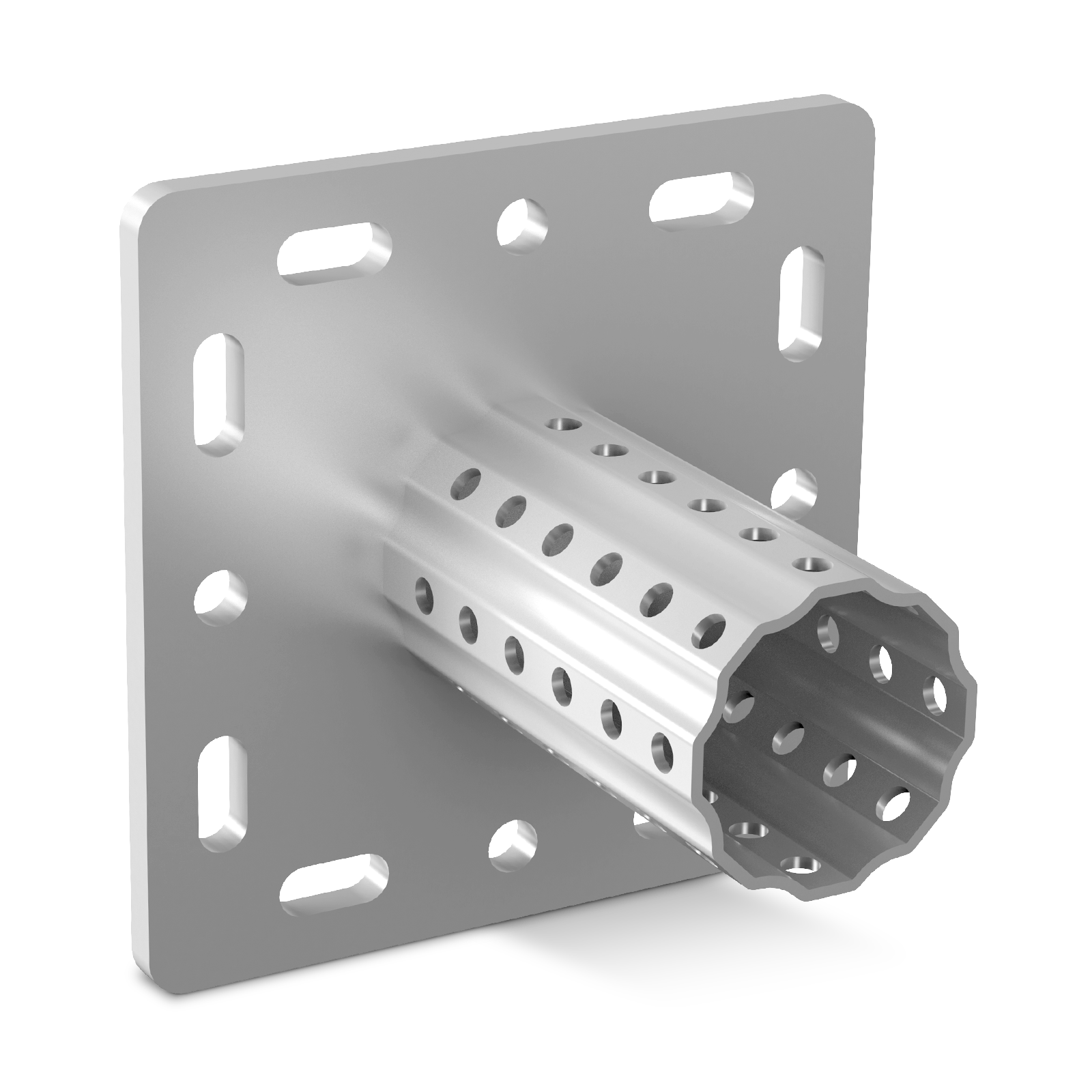

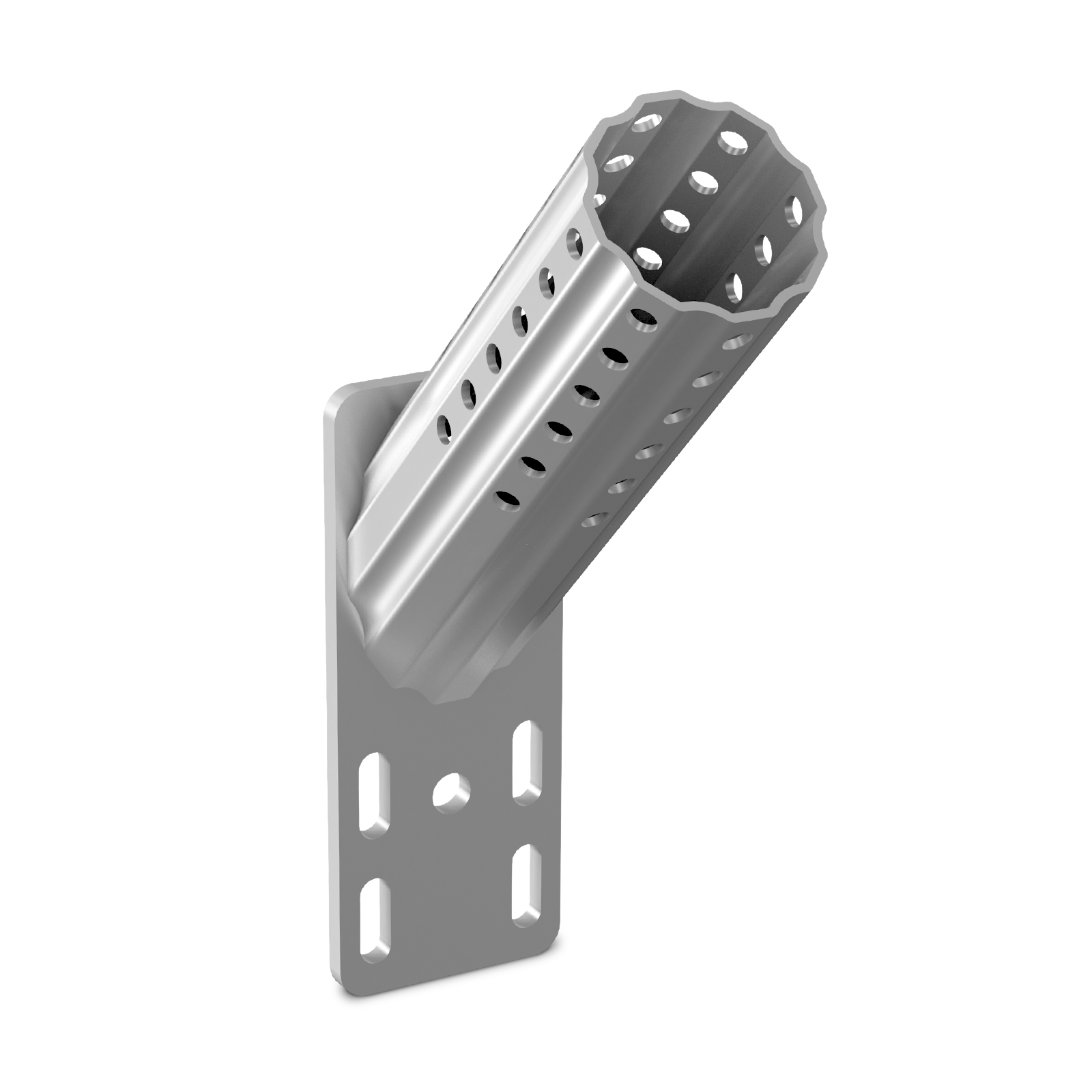

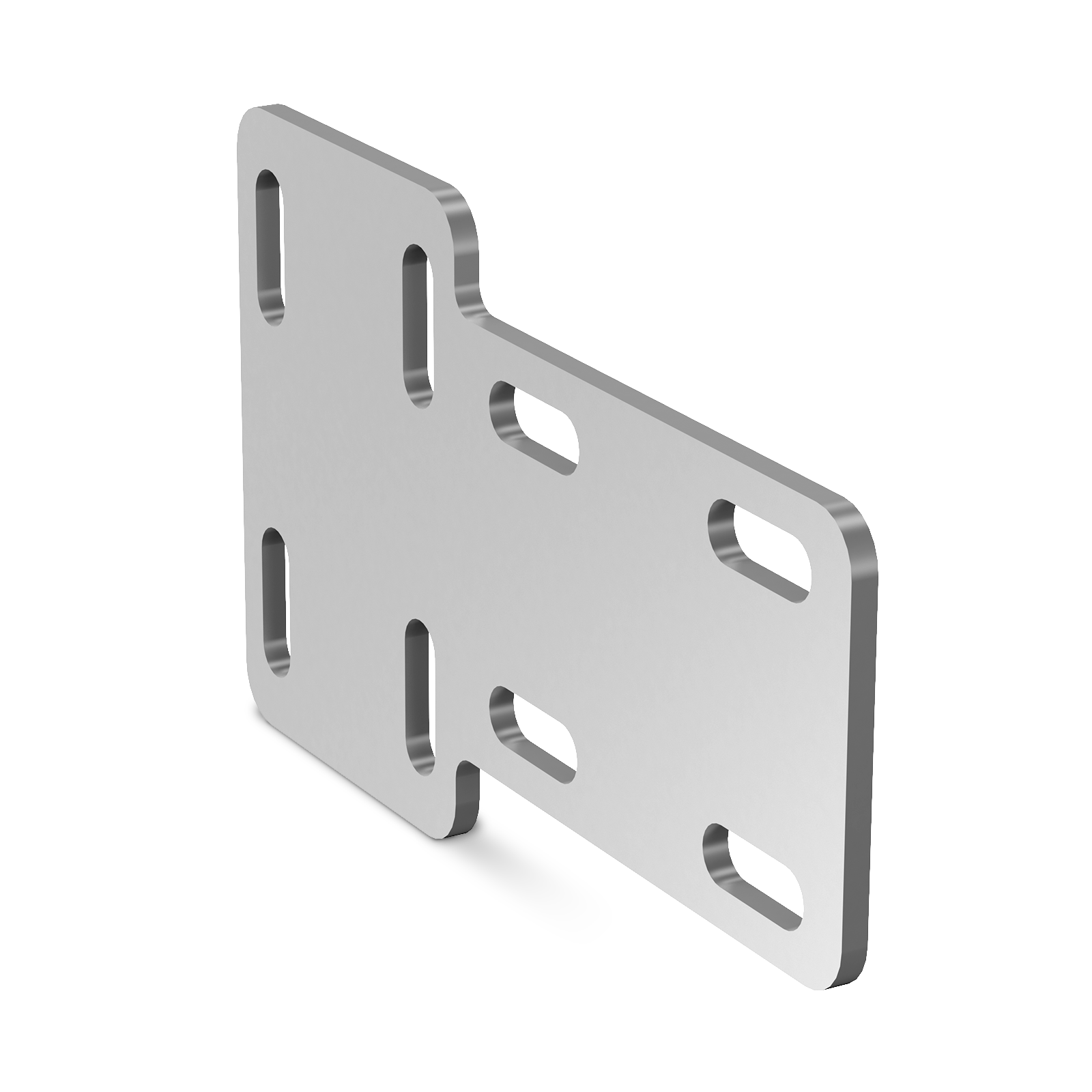

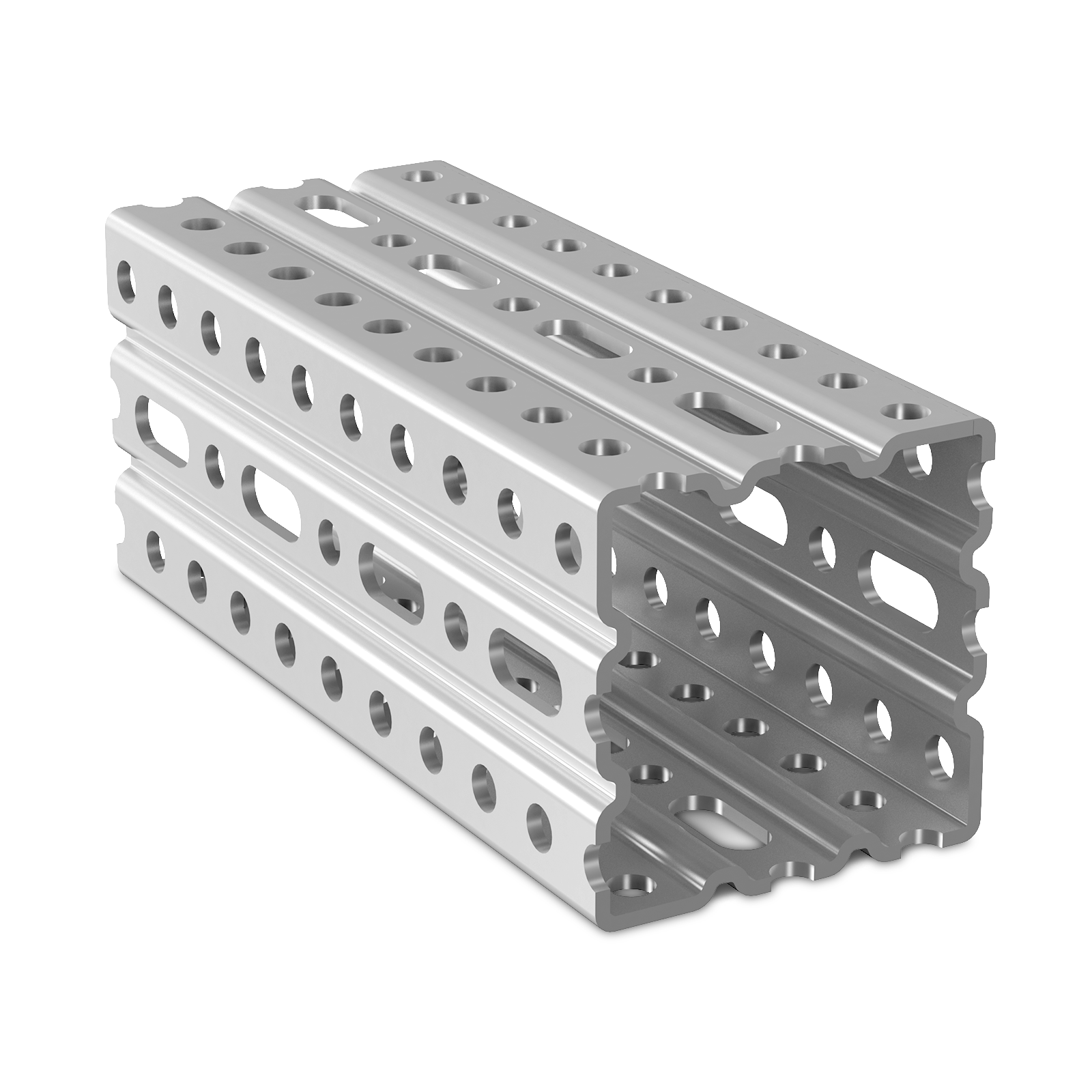

KE heavy channel.

Corrosion protection: hot-dip galvanized

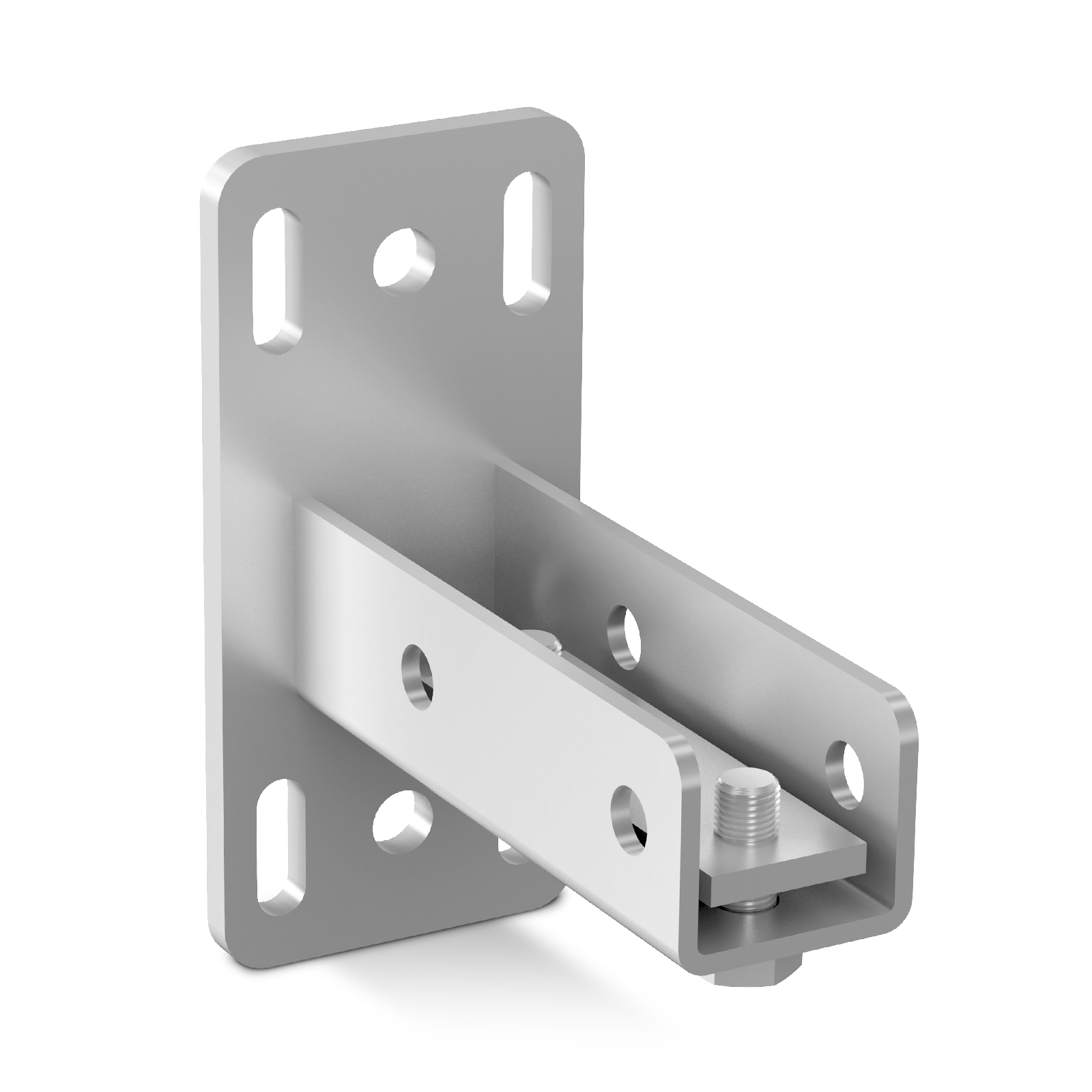

Application: Constructing beams (horizontal). Constructing pillars. Constructing various frames and spatial structures using other system components (connectors, supports, brackets, rungs)

Installation method: Installation of CERTA system components to the KE channel is carried out as follows:- in case of elements installed inside the channel through longitudinal holes, - in case of elements installed outside through Ø9.1 mm round holes One hole is intended for only one self-threading bolt. The number of bolts used for installation depends on the type of product being installed. Tighten the XPCSPM10X21 bolt with a torque of 60 Nm