version

-

Products

PDF Catalog

- Product news

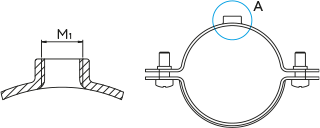

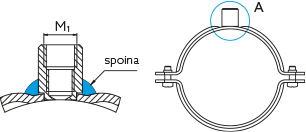

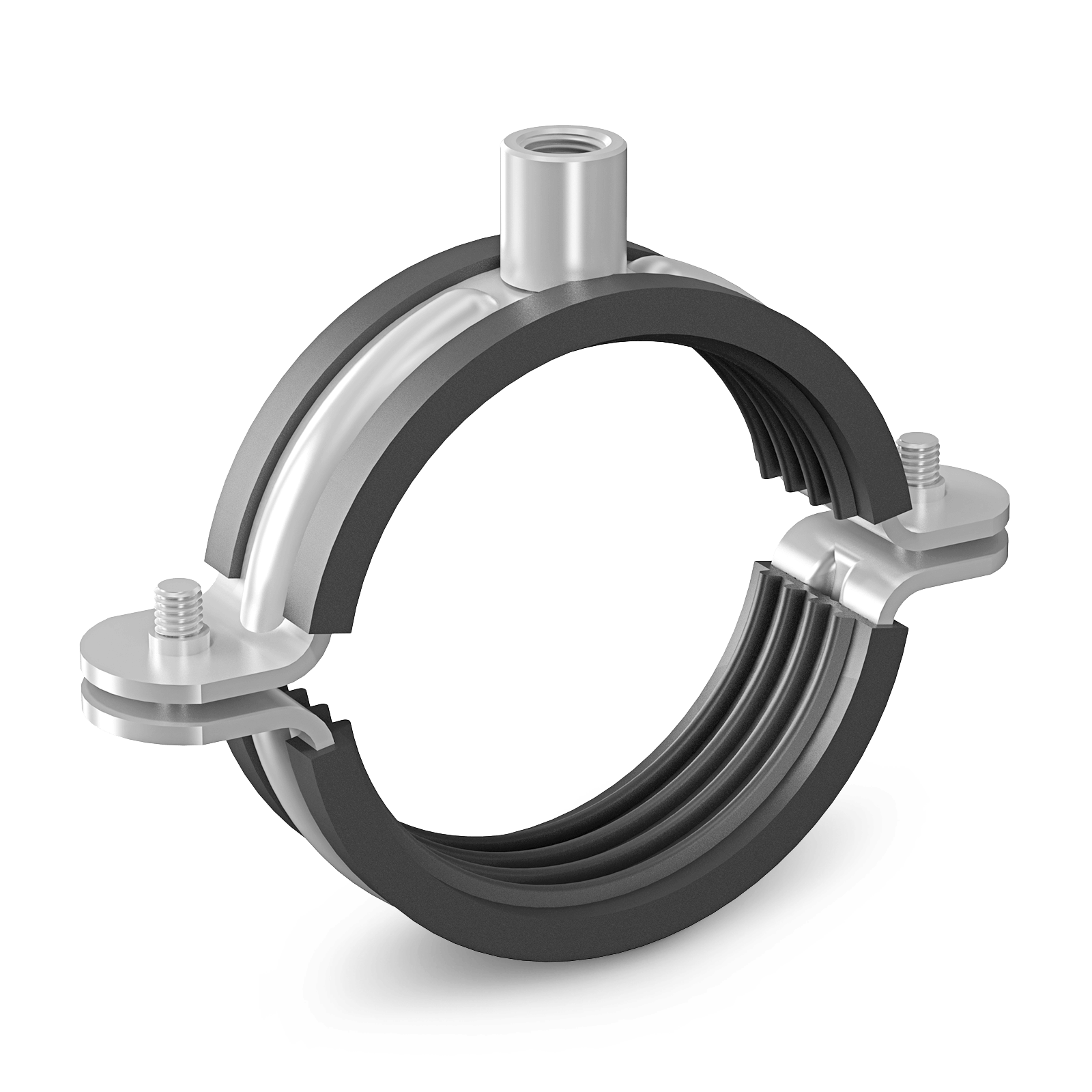

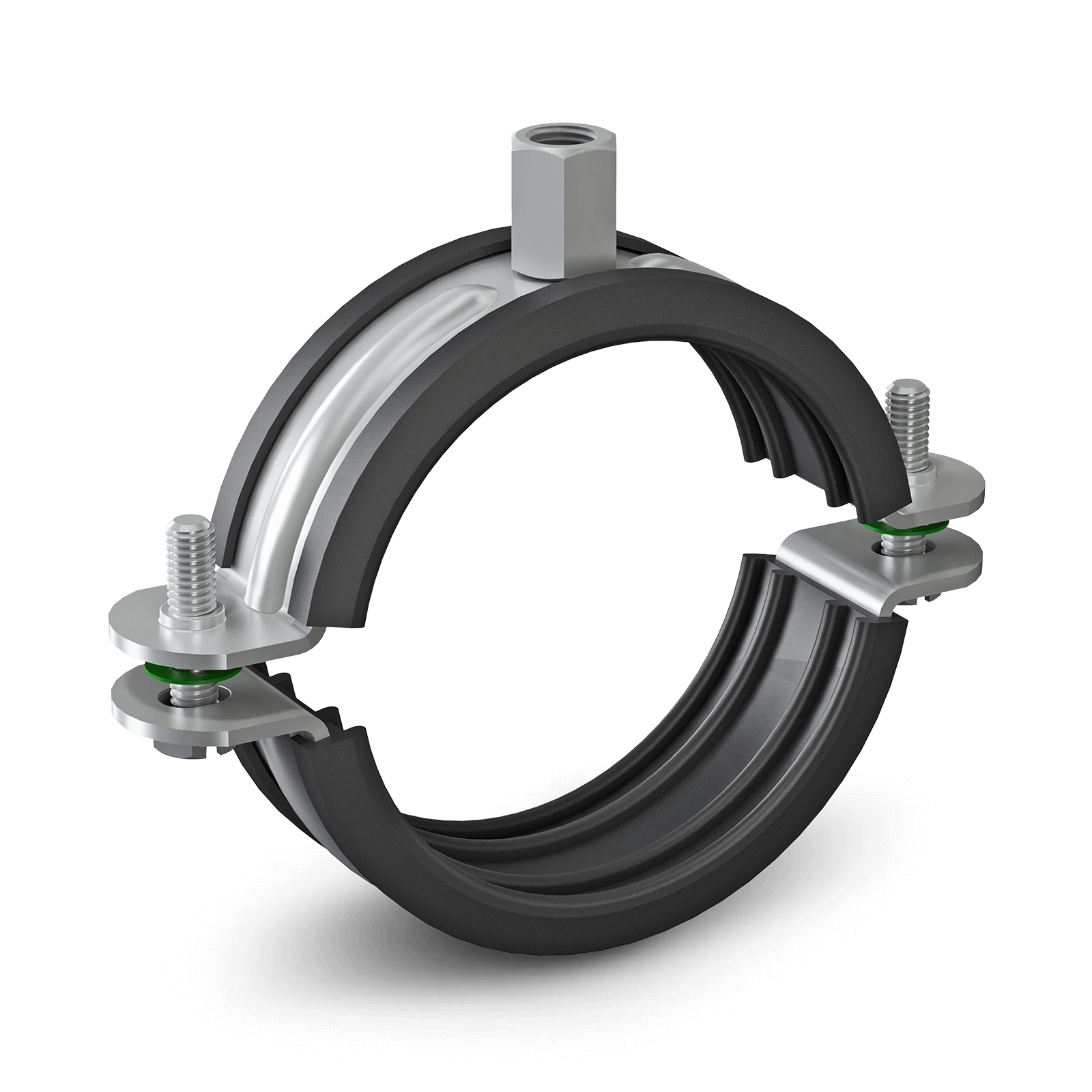

- Pipe clamps with lining

- Pipe clamps without lining

- Fixed points and sliding plates

- Vibration isolators

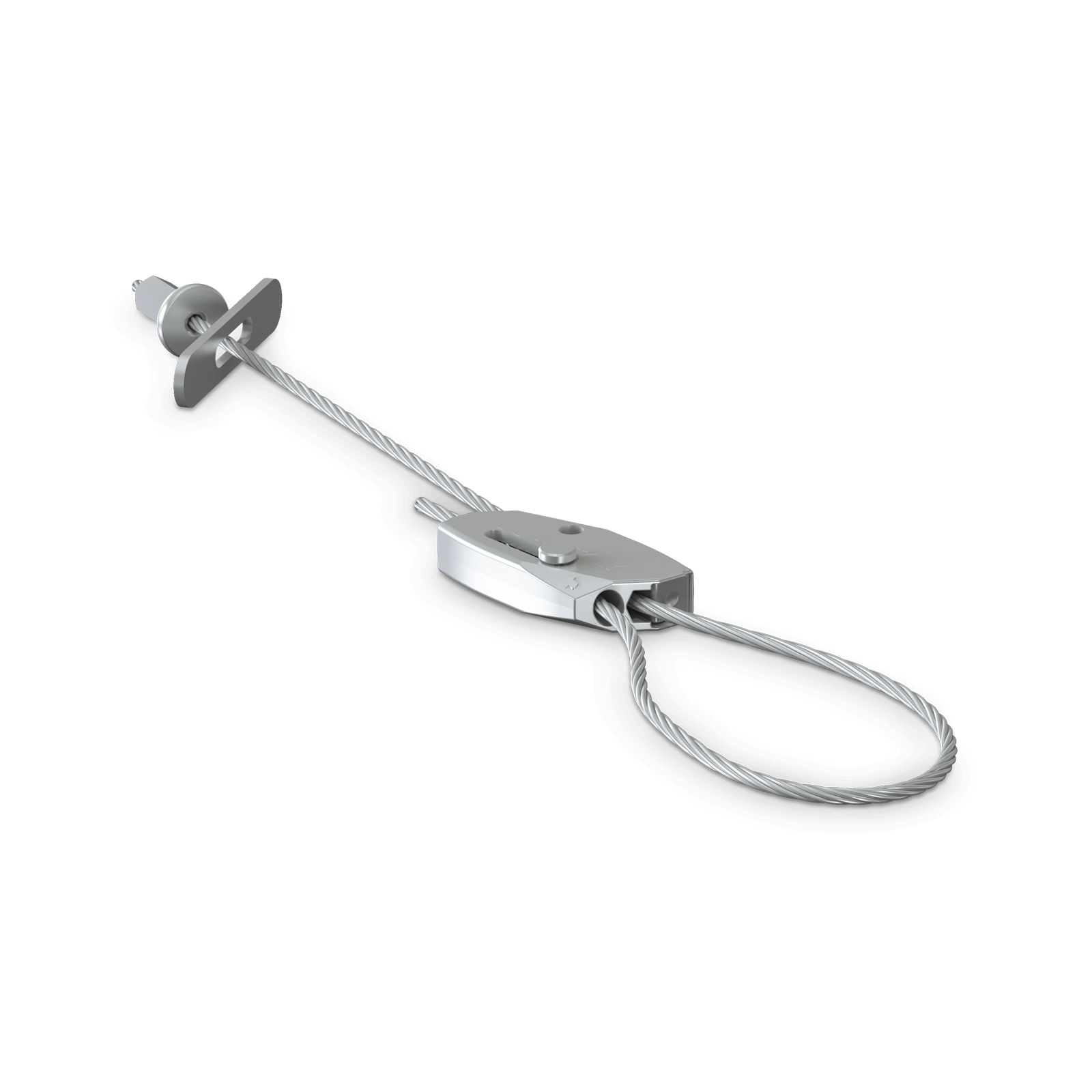

- Wire rope suspension system

- Pipe clamps and ventilation accesories

- Roof support and service platform system

- Support kits

- Fire protection system

- Firestop and protection systems

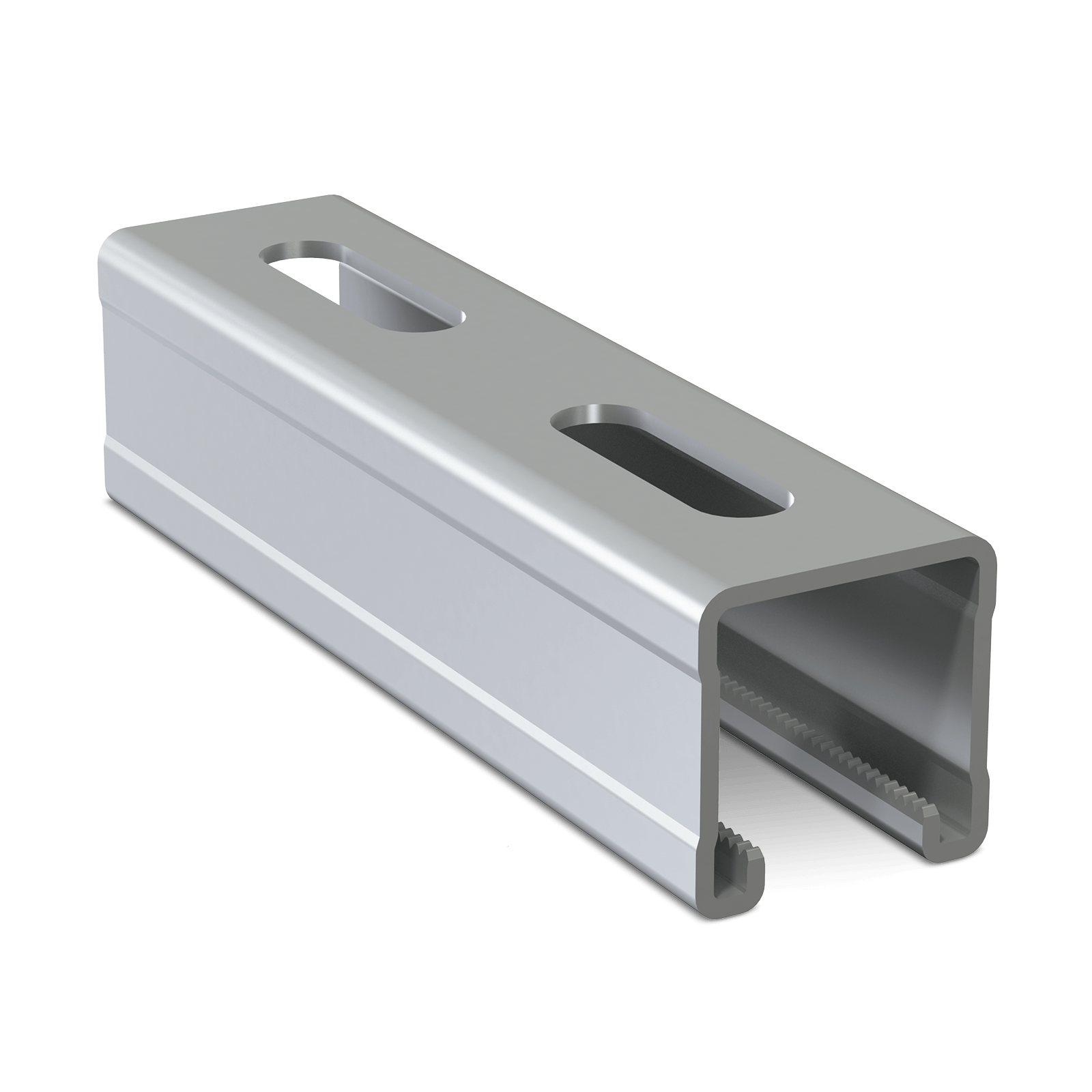

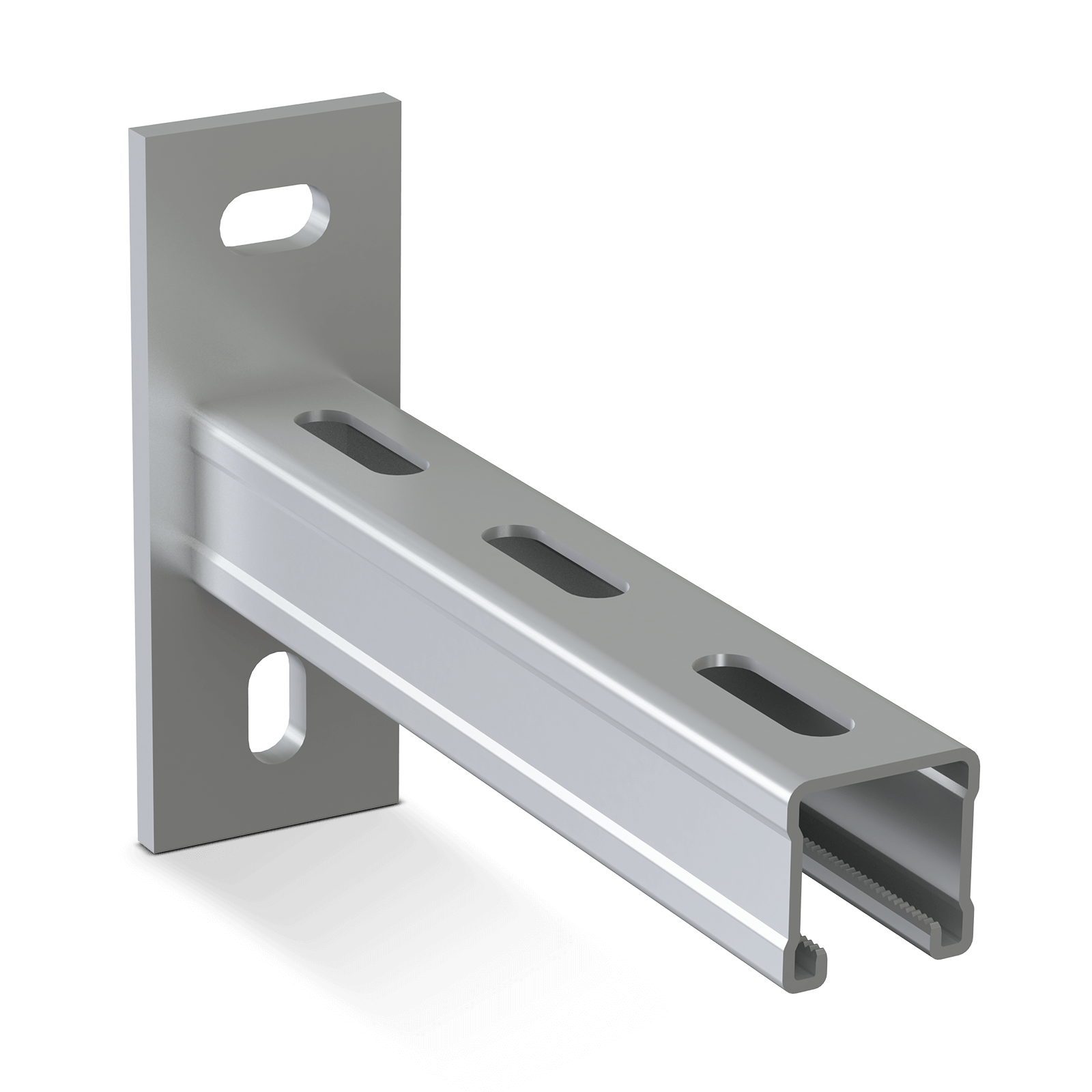

- Channels

- Channels accesories

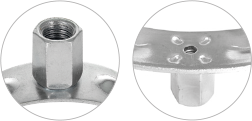

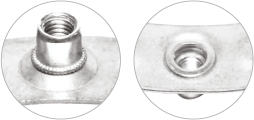

- Fastening and connecting elements

- Anchor fixings

- Installer’s work ergonomics

- Stainless steel products (A2)

- Hot-dip galvanized products

- Ultra Cover XP products

- CERTA heavy channel system

-

Distributor’s zone

EN

CONVEYORS

EN

-

Products

PDF Catalog

- Products

- Product news

- Pipe clamps with lining

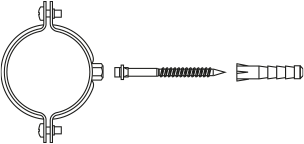

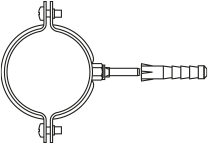

- Pipe clamps without lining

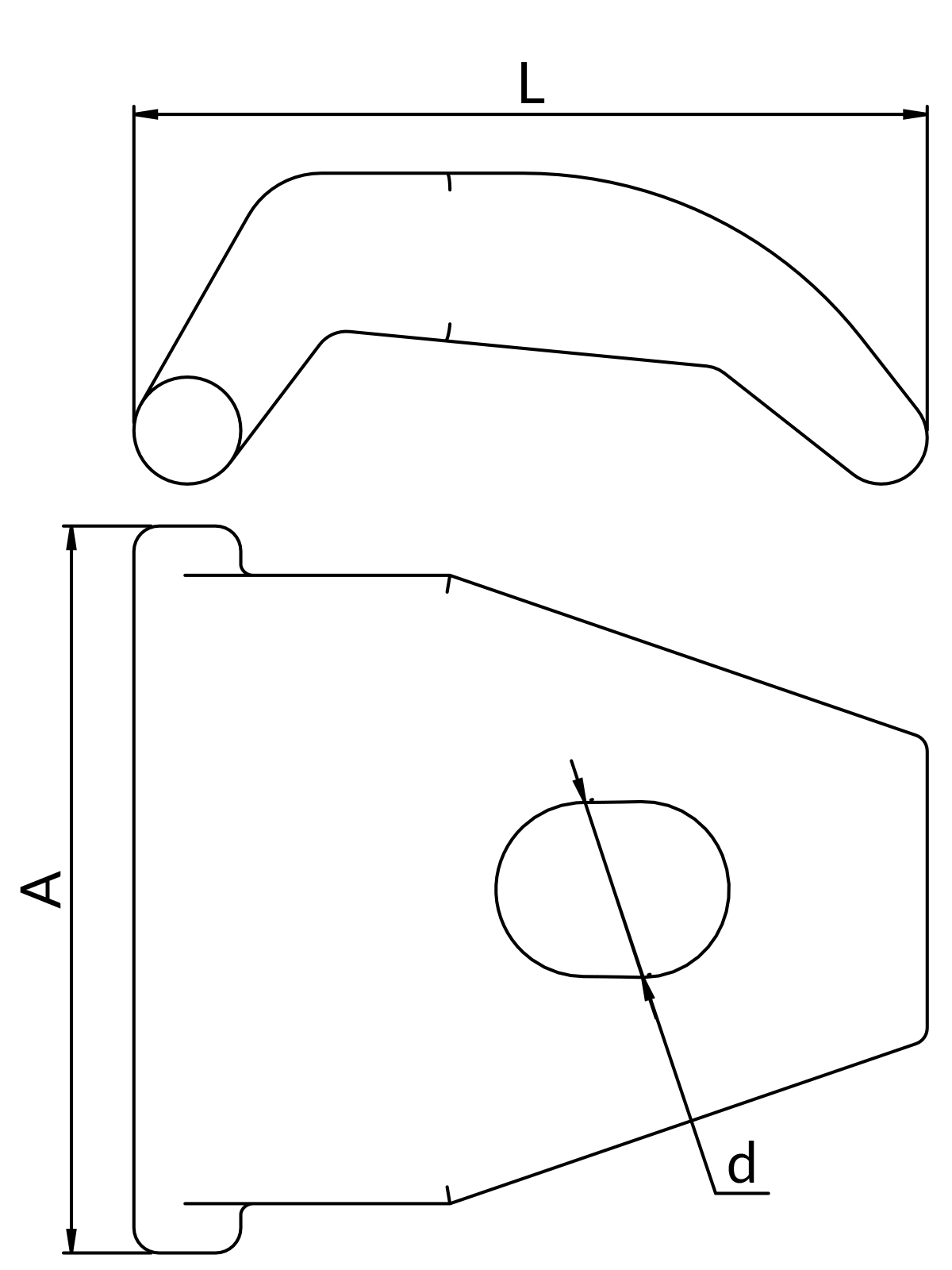

- Fixed points and sliding plates

- Vibration isolators

- Wire rope suspension system

- Pipe clamps and ventilation accesories

- Roof support and service platform system

- Support kits

- Fire protection system

- Firestop and protection systems

- Channels

- Channels accesories

- Fastening and connecting elements

- Anchor fixings

- Installer’s work ergonomics

- Stainless steel products (A2)

- Hot-dip galvanized products

- Ultra Cover XP products

- CERTA heavy channel system

-

Distributor’s zone

enable chat notification sound